1. Introduction

1.1. Aircraft

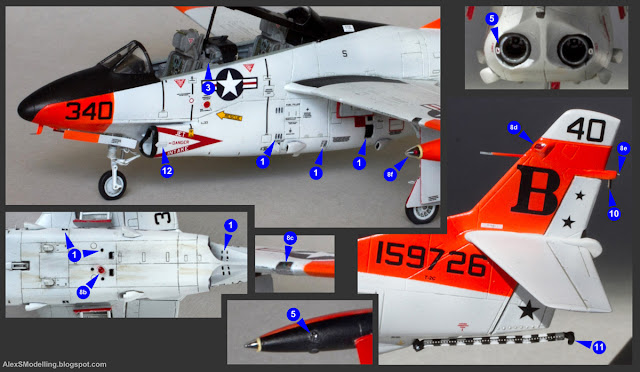

North American T-2C Buckeye

Carrier-capable jet training aircraft (information in Wikipedia)

U.S. Navy. BuNo 159726 / B340. VT-23 squadron.

NAS Kingsville, USA, 1982.

1.2. Story

A T-2C of Training Squadron 23 is being prepared for a routine training flight, with a ground crewman operating the NC-8A mobile power unit to start the Buckeye's engine.

1.3. Model Kit

T-2C Buckeye from Wolfpack Design (kit # 10005), 1:72 scale.

2. Kit Overview

The T-2C produced by Wolfpack Design from Korea is a very good kit. Its key features include very good overall accuracy, high quality of moulds and commendable level of out-of-the-box detail.

Yet there are some minor flaws that have to be addressed:

- The main wheel hubs are not especially accurate and the nose wheel is moulded as one piece with the gear leg, which is unrealistic.

- Unfortunately, no intake trunks are provided, and the fit between the intakes themselves and the fuselage is less than ideal.

- The joint between the wing and the fuselage is weak: the plastic tabs are too small and do nothing to provide the wing with the correct dihedral.

3. Construction

3.1. Building

1) Various fuselage inlets and vents were cut out (dark wash would not suffice to realistically imitate these, in my view), with interior imitated where visible through the larger ones.

2) Instrument panels and ejection seats were detailed with the photo-etched metal set produced by Eduard (set #73534). The set is good, and it renders an expensive after-market resin cockpit unnecessary (the Eduard's PE set is not cheap either, but it helps to detail the whole of the airframe and not just the cockpit).

3) Still, the interior area between the two seats needs more detailing: canopy lifting arm, canopy defrosting system piping and some electrical stuff at the back of the rear cockpit instrument panel were scratch-built.

4) Instead of relying on very small plastic tabs, I installed a metal spar to ensure the firm attachment between the wings and the fuselage.

5) Engine exhaust area was detailed with scratch-built metal tubes (I don't know their purpose but they are clearly seen on all T-2C photos).

6) The nose landing gear leg was rebuilt, with scratch-built metal oleo, photo-etched scissor link and tie-down rings (Eduard) and resin wheel (ResKit set #72-0124).

7) Main landing gear was similarly detailed with metal oleos, photo-etched scissor links and tie-down rings and resin wheels (ResKit).

8) As usual, external lights require quite a lot of attention:

a) clear landing light is fine out of the box;

b) clear red ventral anti-collision light was scratch-built;

c) carrier approach lights cluster, located on the port wing leading edge, had to be scratch-built too;

d) and the clear red anti-collision light, very prominently located at the vertical stabilizer leading edge, also had to be scratch-built;

e) scratch-built clear white navigation light was added to the vertical stabilizer fairing;

f) two navigation light cluster on each of the wingtip tanks are the most complicated of all: when you look at the photos of the real thing very closely, you can see that (for whatever reason) each of the two clusters contains two lights – green and red; the items are very small, so I tried to imitate this feature as best as I could.

9) Some scratch-built details were added to wingtip tanks: fuel level check windows; fuel dump outlets at their aft ends.

10) Scratch-built fuel dump pipe was added to the vertical stabilizer fairing.

11) The Buckeye possesses an unusually perforated tailhook. Assembling the Eduard's photo-etched parts is tricky, but the effect is worth the effort.

12) Scratch-built "bulges" (antennae?) added to the intake lips.

Flaps are in neutral position and speed brakes are, of course, closed, as it must be on a parked Buckeye in normal conditions.

3.2. Painting & Markings

My Buckeye model carriers the International Orange over Insignia White camouflage scheme, typical for the Navy's training aircraft of the period. Miscellaneous markings are all done in accordance with historical photographs and include jet intake lips, wing tanks inner sections, anti-glare panel and canopy "mask" painted black, and landing gear door edges painted Insignia Red.

The Wolfpack kit provides nice decals. However, I wanted to have a smart-looking black-masked aircraft of VT-23, and therefore I used a couple of items from the Two Bobs decal # 72089 sheet (obtained a long time ago when the only available Buckeye kit was the elderly Matchbox, with fatally "yellowed" decals), and some from a generic decal sheet produced by Techmod.

3.3. Presentation

The presentation of this model is very simple; it includes the following:

1) The diorama base is sheet plastic, painted by myself in accordance with historical photographs of the Buckeyes seen on the ramp of NAS Kingsville.

2) The NC-8A mobile power unit is a kit produced by F4Models (cat. # 7025). This purpose-built land-based vehicle, designed to provide external electric power to aircraft for pre-flight or maintenance purposes, was in service with the U.S. Navy and Marine Corps from the early 1970s until the late 1990s and powered many types of aircraft, including the T-2 Buckeye.

3) The ground crewman figure came from a CMK set (# 72117).

4) A hand-held or a cart-mounted fire extinguisher is a common sight on any Naval Air Station. Photographs of NAS Kingsville indicate that there the fire extinguishers were kept in small wire-mesh boxes. The box is scratch-built, while the fire extinguisher is from Aerobonus set (# 720013).

4. Reference Data

[1] Basic information on the T-2 Buckeye in Wikipedia: link, including a good set of historical photographs: link.

[2] North American T-2 Buckeye | Naval Fighters Series # 15 | Ginter Books, 1987.

5. Notes

5.1. In the main text, I said that the Wolfpack kit tabs for attaching the wings to the fuselage are weak. But at least they exist. Whereas on virtually every 1:72 scale plastic airplane model kit produced in the Czech Republic (excepting kits coming from Eduard) there is no provision whatsoever to attach the wing & horizontal stabilizer to the fuselage. I wonder why is this so? What exactly is so deficient in the technology being used by most of the Czech firms that prevents them from making an opening in the fuselage and a corresponding protruding tab on the other part, so that a modeller is not forced to resort to guesswork and scratchbuilding in such a basic operation as a wing / horizontal stabilizer to fuselage joint?

Don't get me wrong, I like model kits made in Czech Republic: they tackle many exotic and lesser known subjects, a number of their model kits are quite accurate, and some are very well detailed. But why can't they do this seemingly very simple thing? It is all the more puzzling because other types of openings – such as fuselage windows, inlets and exhausts, landing gear bay cutouts – are somehow "allowed" by their technology, as can be clearly seen on my comparison photo.